Jaws

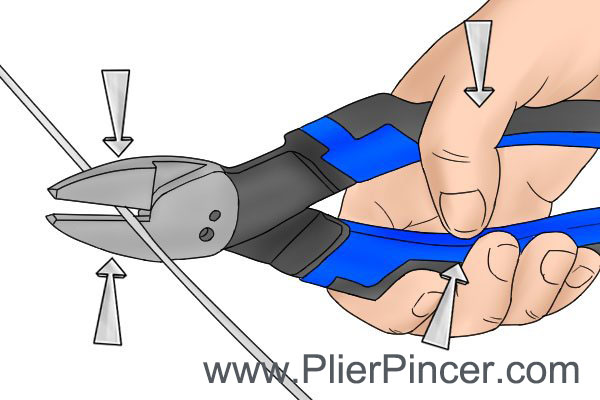

The jaws of diagonal cutting pliers are opened and closed using the handles. They put force onto the wire so the blades can cut through it.

The thickness of the jaws affects the durability of the tool. Thick-sided jaws provide a stable, strong cut along the entire length of the blades.

Thinner jaws offer more precision but lack durability when cutting harder materials.

Blades

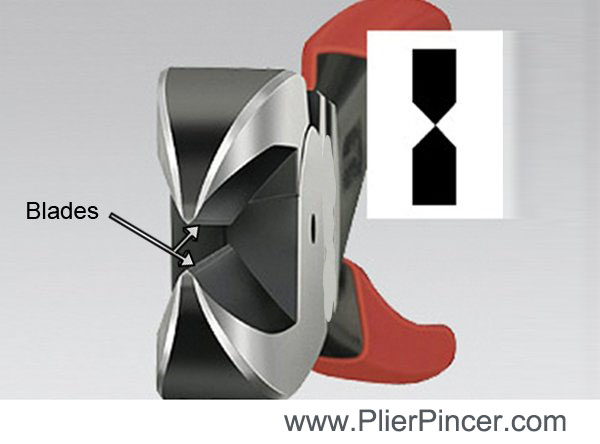

The sharp cutting blades of diagonal cutting pliers are found on the inside edges of the jaws. The force from the jaws pushes them through the material being cut. Hardness Rockwell tester HRC used to test blades of diagonal side cutting pliers, nippers, wire cutters.

The blades have to be very hard to push through the material. The hardness of the blades is tested and given a ‘Hardness Rockwell category C’ (HRC) number. You should expect diagonal cutting pliers blades to be HRC60-65.

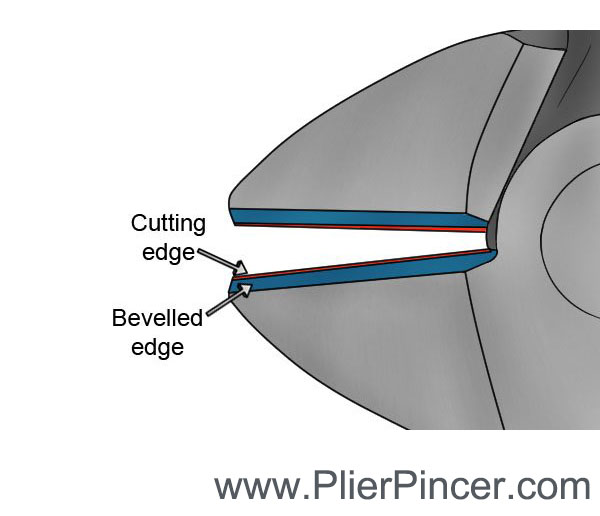

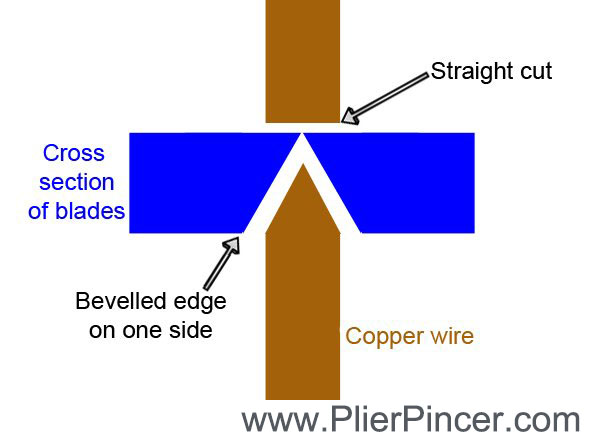

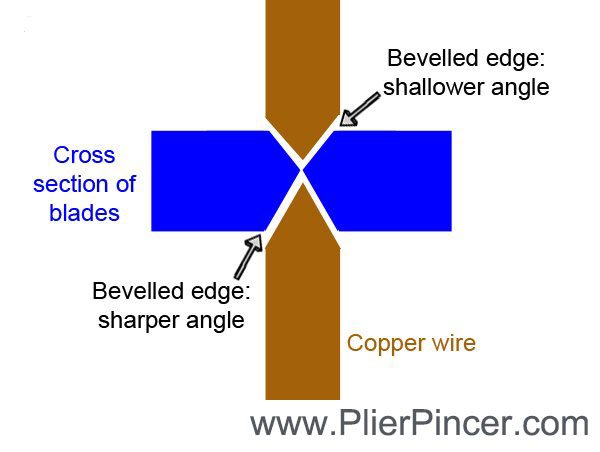

The edges of diagonal cutting pliers blades are bevelled leading down to the cutting edge. This allows the jaws to be much thicker than the cutting edge to provide strength and support. The cutting edges can be bevelled on both sides or just one side.

A bevel on just one side makes the blades less tough and cutting harder materials could easily cause them to break. The advantage is they can cut wires flush against a surface because they can create a straight cut on one side.

Diagonal cutting pliers with bevels on both sides are much more strong and durable. Having the cutting edge in the centre of the jaw with both bevels at the same angle is the strongest configuration but will not cut a wire flush to a surface. Many diagonal cutting pliers have one bevel at a shallower angle as a compromise between strength and a flush cut.

On most diagonal cutting pliers, the blade continues along the entire length of the jaw’s inside edge but some models ‘offset’ the blades so that they finish a little before the tip of the jaw. This design is to protect the blades from damage if the tool is dropped.

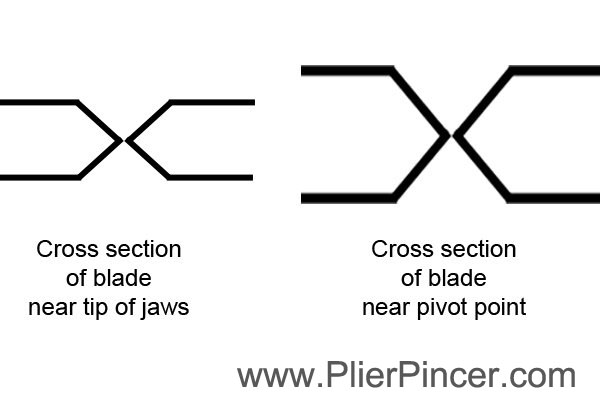

Some blades have ‘progressive edges’ which means the blade is finer at the tip of the jaws and thicker at the base of the jaws, nearest the pivot point. This allows precision when cutting soft materials near the tip but without losing the strength required to cut harder materials near the base.

The bevelled edges of a few models of diagonal cutting pliers are engraved. This design is to help prevent the material from slipping away from the joint as it is cut.

Handles

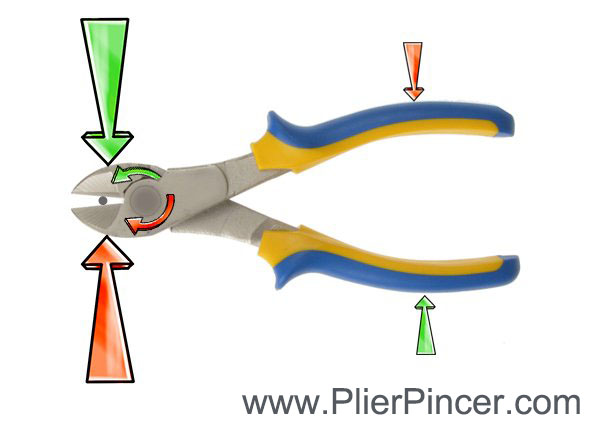

The handles of diagonal cutting pliers work as a pair of levers, transferring the opening and closing action to the jaws (see How do diagonal cutting pliers work?).

They are made from metal but often have a plastic coating for comfort.

The plastic coating is shaped to fit comfortably into the hand. It often has a ‘collar’ nearest the pivot point to prevent the hand from slipping towards the jaws.

Joint

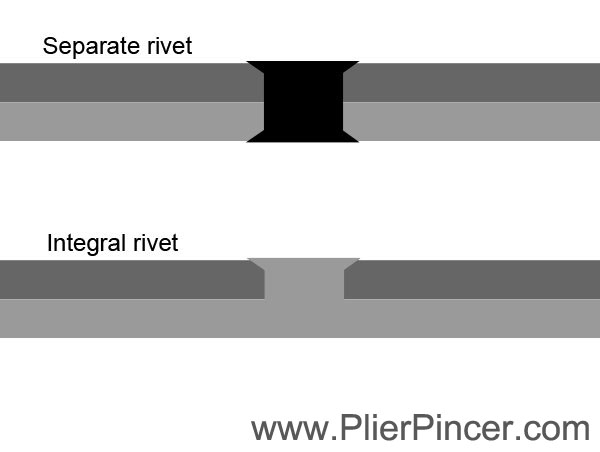

A rivet at the joint of the diagonal cutting pliers joins the pairs of handles and jaws together and keeps them in line with each other, as well as being the pivoting point for the levers (see How do diagonal cutting pliers work?).

Rivets are either made from a separate component that goes through both halves of the diagonal cutting pliers or they are an extension of one half of the pliers that is fixed into the other half.

Some models have extra pivot points which decrease the amount of effort it takes to make a cut. The additional pivots use the physics of levers to increase the force applied to the handles so it is up to 60% easier to cut a material than if you were using standard diagonal cutting pliers. These tools are sometimes known as ‘compound action’ pliers.

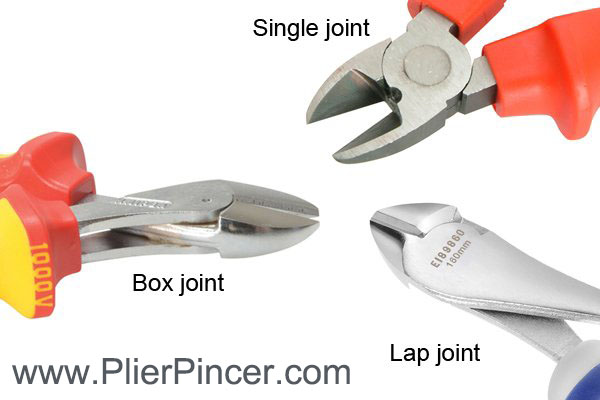

Diagonal cutting pliers use one of three types of joint: lap joint, single joint or box joint. A lap joint is where the two parts of the pliers are laid on top of one another, a single joint is where the parts are set into each other and a box joint is where one part slots through the other. Box joints are the strongest type of joint.