Circlip Pliers for External Circlips, Straight Jaw

Artical No.: HA210320

Standard: DIN 5254 & DIN 5256, ASME B107.19

Size: 5″ 7″ 9″ 13″

Optional Material: Carbon Steel, Chromium-vanadium Steel

Optional Finishing: Black and Polished, Nickel Plated, Chrome Plated

Handles: PVC Dipped Handles

Optional Packaging: Blister Card, Double Blister, Plastic Hanger

Features: The forged construction provides high strength for durability and long life. Durable, rolled precision tips. Die forged cylindrical precision formed. Perfect for removes and installs externally placed retaining rings, widely applied for the fixed bearing or hole bearing in machinery industry, such for bicycles, motorcycle, farm machinery.

Circlip Pliers for Internal Circlips, Straight Jaw

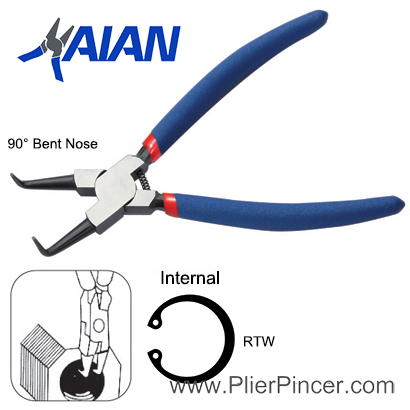

Circlip Pliers for Internal Circlips, Bent Jaw

Circlip Pliers for External Circlips, Straight Jaw

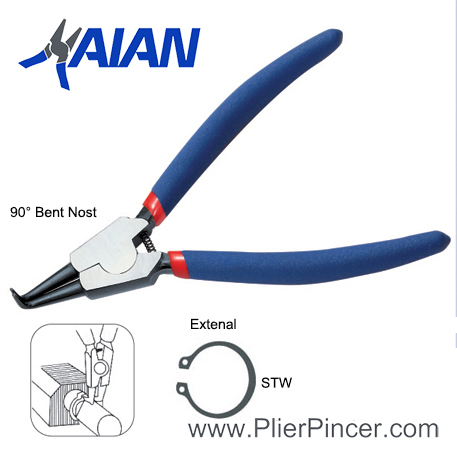

Circlip Pliers for External Circlips, Bent Jaw

| 5″ | 125mm | 1.3mm | 10~22mm | 97g |

| 7″ | 175mm | 1.8mm | 19~60mm | 130g |

| 9″ | 225mm | 2.3mm | 40~100mm | 291g |

| 13″ | 325mm | 3.2mm | 85~140mm | 466g |

| Description | Jaw Opening |

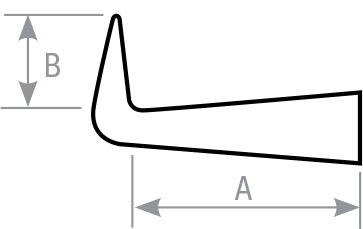

Tip Φ | Tip Length(A) |

Tip Length(B) |

Overall Length |

|

| Internal | Straight Tip | 4~20mm | 1.3mm | 32mm | – | 130mm(5″) |

| Internal | 90° Tip | 4~20mm | 1.3mm | 22mm | 10mm | 130mm(5″) |

| External | Straight Tip | 4~20mm | 1.3mm | 32mm | – | 130mm(5″) |

| External | 90° Tip | 4~20mm | 1.3mm | 22mm | 10mm | 130mm(5″) |

| Internal | Straight Tip | 4~35mm | 1.8mm | 40mm | – | 180mm(7″) |

| Internal | 90° Tip | 4~35mm | 1.8mm | 30mm | 10mm | 180mm(7″) |

| External | Straight Tip | 4~35mm | 1.8mm | 40mm | – | 180mm(7″) |

| External | 90° Tip | 4~35mm | 1.8mm | 30mm | 10mm | 180mm(7″) |

| Internal | Straight Tip | 6~40mm | 2.3mm | 50mm | – | 230mm(9″) |

| Internal | 90° Tip | 6~40mm | 2.3mm | 35mm | 15mm | 230mm(9″) |

| External | Straight Tip | 6~40mm | 2.3mm | 50mm | – | 230mm(9″) |

| External | 90° Tip | 6~40mm | 2.3mm | 35mm | 15mm | 230mm(9″) |

What are Snap Ring Pliers / Circlip Pliers?

Snap Ring pliers (or Circlip Pliers or Retaining Ring Pliers) are a tool designed to install and remove snap rings, which are small metal rings that hold in a bearing or other assembly item by setting into a machined groove. Snap rings are common in car engine parts as well as in motorcycle and bicycle shocks and forks. While the snap-ring pliers are not a tool that will be used often, they are an important addition to a tool box because a snap ring is difficult or impossible to remove or install without them.

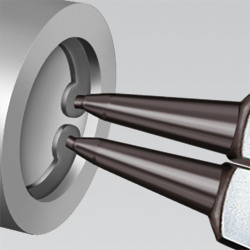

The tool itself looks like a regular set of pliers in a lot of ways. Snap-ring pliers have two arms that act as handles, and they are attached at a pivot point near the head of the tool. Snap-ring pliers have two arms at the tip: these small arms are bent at a ninety degree angle and each one features a small, round tip that will fit into the small, round holes on the snap ring. The snap-ring pliers are sometimes spring-loaded to aid in retracting the tool, and most snap-ring pliers feature a reversible head so the pliers can either pull on the snap ring in one position or push it outward in another position.

The snap ring is a circular metal ring that is broken at one point in the circle. At the break, two small circles are bored into the ends. This is where the snap-ring plier heads will grab onto the snap ring. Once the heads of the snap-ring plier are set into the snap ring holes, the user can squeeze the handles of the plier, which will in turn move the heads either inward or outward, depending on the position of the reversible head. To remove snap rings, the plier heads must move inward to make the snap ring diameter smaller. That way, the snap ring can be pulled out of the machined groove and free of the assembly.

To install a snap ring on the outside of an assembly rather than on the inside as described above, the head of the snap-ring plier must be reversed so the heads push the snap ring holes outward. This makes the diameter of the snap ring larger so it can be placed on the outside of an assembly. Once the snap ring is put into place, the handles of the plier can be released and the snap ring itself will relax into a smaller diameter, settling into the groove in which it should sit.

How to Use Snap Ring Pliers / Circlip Pliers

Snap ring pliers (or circlip pliers or retaining ring pliers) are used to install or remove “circlips” from equipment shafts. A circlip, sometimes called a snap or retaining ring, holds bearings on shafts or within bore holes. Circlips are also used to hold wheels on axles, clutches on chainsaw motors and even faucet cartridges in valve housings. Like circlips, the pliers you use to install and remove them come in multiple sizes, but there just two configurations. Use the proper circlip pliers to simplify the task of removing a ring from a shaft or bore hole.

Step 1

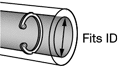

Identify the circlip. Circlips come in two configurations. Internal circlip rings go inside a bore hole and apply pressure to the outside when in place. External rings go around a shaft and apply pressure inward under normal use. The two holes on the circlip can be used to identify the type of ring. Internal circlip rings have the hole inside the perimeter of the circle made by the clip to keep them out of the way of the ring when it is in place. External rings have the holes outside the perimeter of the circle that will go around the shaft.

Step 2

Select the right circlip pliers. Circlip pliers look somewhat like standard needle-nose pliers with small prongs at the end of each jaw. Interior-ring circlip pliers have jaws that close as the handles are compressed. This compresses the ring inward when the prongs on the ends of the jaws are inserted into the holes in the circlip ring. External-ring circlip pliers have jaws that spread when the handles are compressed to open the circlip ring and allow its removal from the shaft.

Step 3

Use the right size pliers. Pliers that are too small may not provide enough leverage to remove the circlip ring from the shaft or bore hole, while pliers that are too big are difficult to use and may have prongs too large for the holes in the circlip rings.

Step 4

Install an exterior circlip by hooking the ends of the pliers to the loops on either end of the ring and opening the jaws of the pliers. Slide the ring into position, release the handle and remove the pliers.

Step 5

Place an interior circlip by hooking the jaws on the circlip ring and closing them to compress the ring. Slip the ring into position inside a pipe or fitting, allow the jaws to open and remove the pliers.

Reviews

There are no reviews yet.